Making historical replicas

Mostly is supposed, Germans didn´t put importance) on bows. But this don´t mean they didn´t use them at all. Because we don´t find the bows in burial grounds, they used them probably for hunting, not for fight. Discovery of bows in Nydam (1863, south Denmark)shows increasing importance of this weapon. These bows were dated to the Roman age(200-400 A.CH.) Angels and Saxon, who were settled in this area and who later expanded to Britain, probably carried along also own bows and arrows.

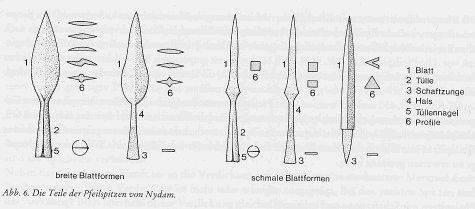

Arrowheads from Nydam are mainly made from iron, but were also found arrowheads from horn or bone. Some of the heads are laurer-leaf shaped, used both for hunt and for fight. More often are needle arrowheads, which can penetrate ring mail and buckler. These heads are similar to middle-age bodkins. Founded broadheads have cone, while bodkin-type heads have spindle.

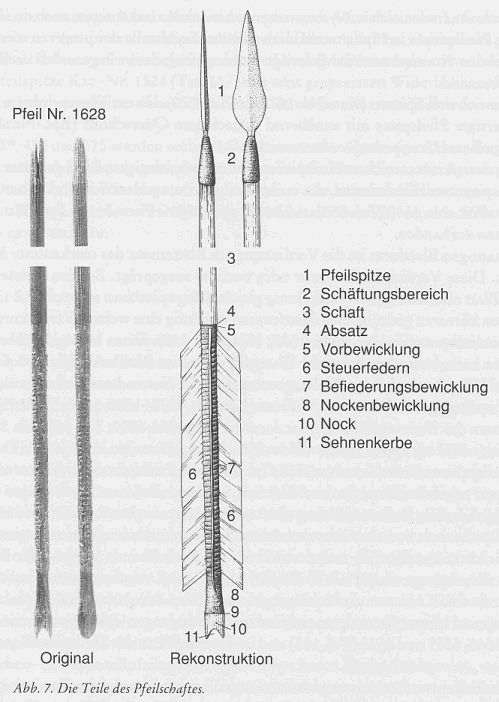

Founded arrows have shafts made of ash or pine. Pine arrows have 6-20 growth rings in 1 cm, ash shafts 2-7 growth rings in 1 cm. Lenght of shafts vary from 63-85,4 cm. The diameter of the shafts is 8-10 mm. On the shafts there are different scrapes, may be marks of producer or owner. All arrows are worked in good quality. Sometimes a lot of repairs can be seen on arrow. This can mean new shaft were difficult or too expensive to make.

Fletching of the arrows were made of different bird feather. Fully was found 9 species of bird feathers (e.g. goose, swan, eagle etc.). Feathers were fixed to the shaft with fibre(tree phloem) 22-76 turns in 10 cm. It were used 4 fletches fixed in X or cross position. The length of feathers vary from 8 cm to 13 cm.

Feathers and fibre were glued with birch tree tar.

The nocks are widen and string cut is U or V shaped. Width and depth of nock is 0,5 cm x 0,5 cm.

Autor: O. Fröhlich (Iwaz)

Sources:

- Bögen und Pfeile v Der Opferplatz von Nydam by Harm Paulsen

- Internet

Based on above written article,I tried to make arrows in this manner. I started with ash shafts, white goose feathers, fibre(tree phloem), beech tar and hand-forged arrowhead bodkin and broadhead type.

Shafts are from sawed wood, because ash is very difficult to split. Than it is hand planed to the necessary diameter. The part of future feathers is weakened by spokeshave and nock is hand cut and filed by needle file. Prepared shaft in this phase you can see in the picture below.

Feathers are prepared as usually, i.e. cutting from the quill and arranging to the suitable dimension - 12 cm(4,7") long and approx. 1,5cm(0,7") high. For each arrow I need 4 even feathers.

To fix all the feather with one piece of fibre, you need circa 1 m long fibre. This fibre must be as thin as possibly, and can be prepared by dividing of one fibre to thinner and thinner parts along all the length. This claims very patient work, because thin fibre are easy to break.

Prepared phloem

Now start wrapping of feathers with phloem. I make wrapping at the beginning of feathers and go on to the end of fletch. This part of work is very time consuming. Finally are feathers fixed to the shafts.

Prepared shaft, wrapped shaft

The cone-type arrowhead is put on the prepared shaft and saved with forged nail. If I use arrowhead with spindle, I make long nock into the shaft, insert arrowhead and tie on with phloem fibre.

After this I heaten beech tar. It must be heatened in the fire, because it need high temperature to became liquid. In the normal condition it is hard as a stone. When the tar has suitable consistency, I paste it on the wrapping of feathers and arrowheads. When it became cold, it is hard and protect the phloem against breaking.

Detail of completed fletching, glued with wood tar

Feathers creating X

Hand forged bodkin, saved with nail and wood tar

One arrow takes about 2 hours of work. If I use wood splitting to prepare the shafts, it would be even more. But the result is nice. And when the arrow flies through the air...